Contact Us

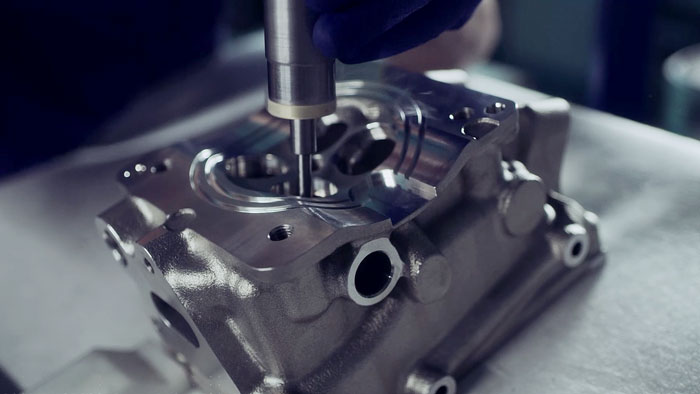

ACTech is always at your side as a reliable partner, from the starting gun to the finish line. Our work is not complete until you hold your part in your hands ready for assembly. This is why we accept no compromises when it comes to finished part finishing and quality testing, and we assume these tasks ourselves.

Professional pre-assembly and assembly of complex part groups

Extensive options for finished part treatment according to needs

Certified quality assurance including detailed test documentation