Is your part highly complex, does it require absolute precision and should it ideally have been finished yesterday? Where other foundries thankfully decline, ACTech gets into the swing of things. When you go "all in" with us, rest assured: We complete the production of your castings on time and with high precision – even within very tight time schedules.

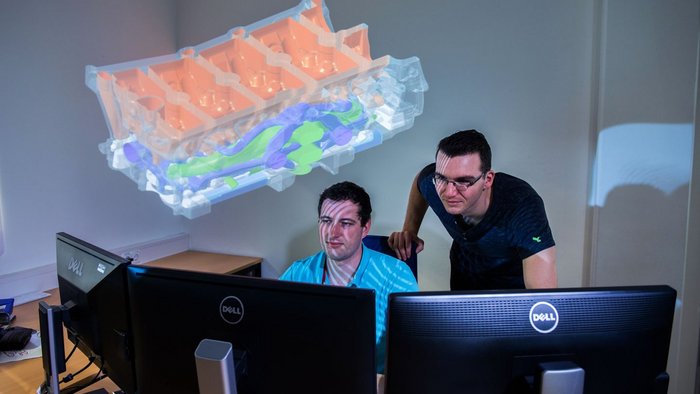

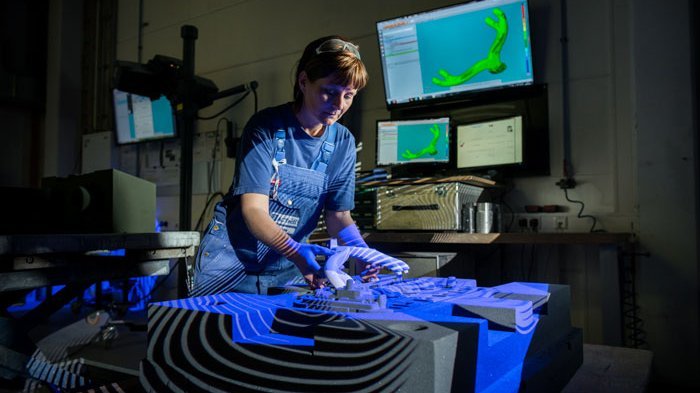

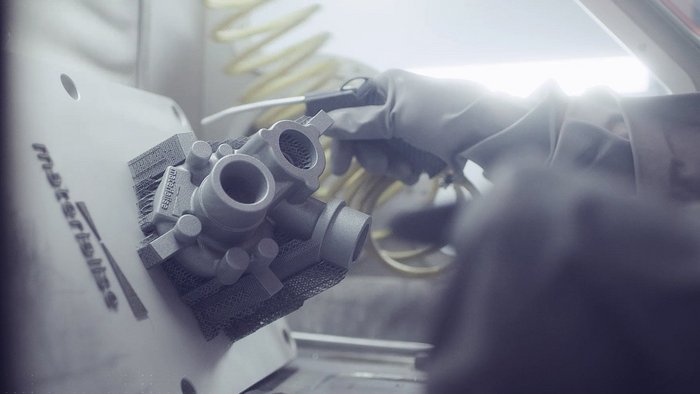

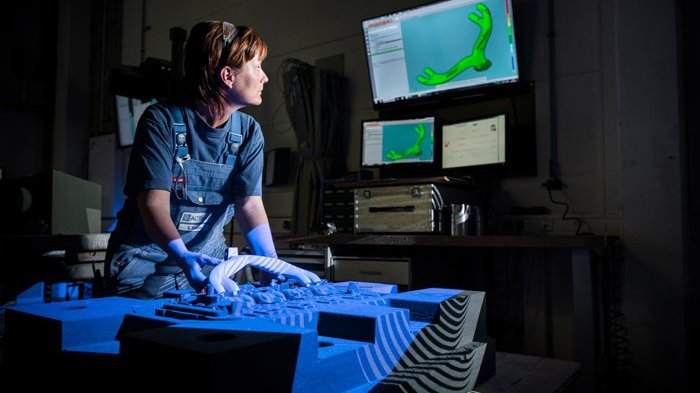

Our mission: We produce highly complex prototypes and small batches in metal within the shortest possible times and with absolute precision. To achieve this, we focus on two production processes: metal casting and metal 3D printing. In our foundry we produce castings in sand casting. Selection of the appropriate process depends, among other factors, on your requirements for the part in terms of complexity, quantity, wall thickness and surface finish.

Perfectly optimized process flows

Good is not good enough for us! This is why ACTech is constantly evolving: We regularly review the use of new technologies and production facilities and optimize our workflows in terms of quality assurance and time savings. Our objective: to accelerate prototype production, shorten lead times and guarantee best support for customers.

Our effectiveness is the reason customers go 'all in' with us time and time again. Whether metal casting or additive manufacturing, with prototyping we're the leaders as well as being champions of diversity: In more than 30 years we've produced over 250,000 prototypes in metal and more than 40,000 constructions – for numerous industries and customers from all over the world. No matter how demanding your part is, our team of highly qualified specialists develops the right solution for you.

What does go "all in" at ACTech mean?

What does go "all in" at ACTech mean?

At ACTech we 'go All in' and that means two things. Firstly, we rely on internal solutions – you get all casting and CNC machining processes from a single source. This makes us more independent, more reliable and faster than others. Secondly, it means our high level of commitment with every project and every challenge. We commit all resources to help you bring your project to life.

What are the advantages of ordering prototypes instead of directly ordering batch parts?

What are the advantages of ordering prototypes instead of directly ordering batch parts?

Prototyping is an important part of the design process. You can think of it a little like an insurance policy. Before you invest in a full batch, you should make sure your design meets the requirements. Reliability is of decisive importance, and it's something you can achieve with rapid prototyping. The initial investment may seem connected with high costs, but doing it right the first time will save you time, money, and materials in the long run.

Does ACTech also offer CNC machining?

Does ACTech also offer CNC machining?

CNC machining is part of our 'all in' concept and we base this on the many years of experience we have in this field. Our advantage lies in our extensive CNC machine park with over 20 machining centers, shuttle table system and state of the art tool management. This gives us very high levels of flexibility in terms of using different machining equipment, diverse sizes and various machining processes – we can switch from milling to turning and combine the two.