Contact Us

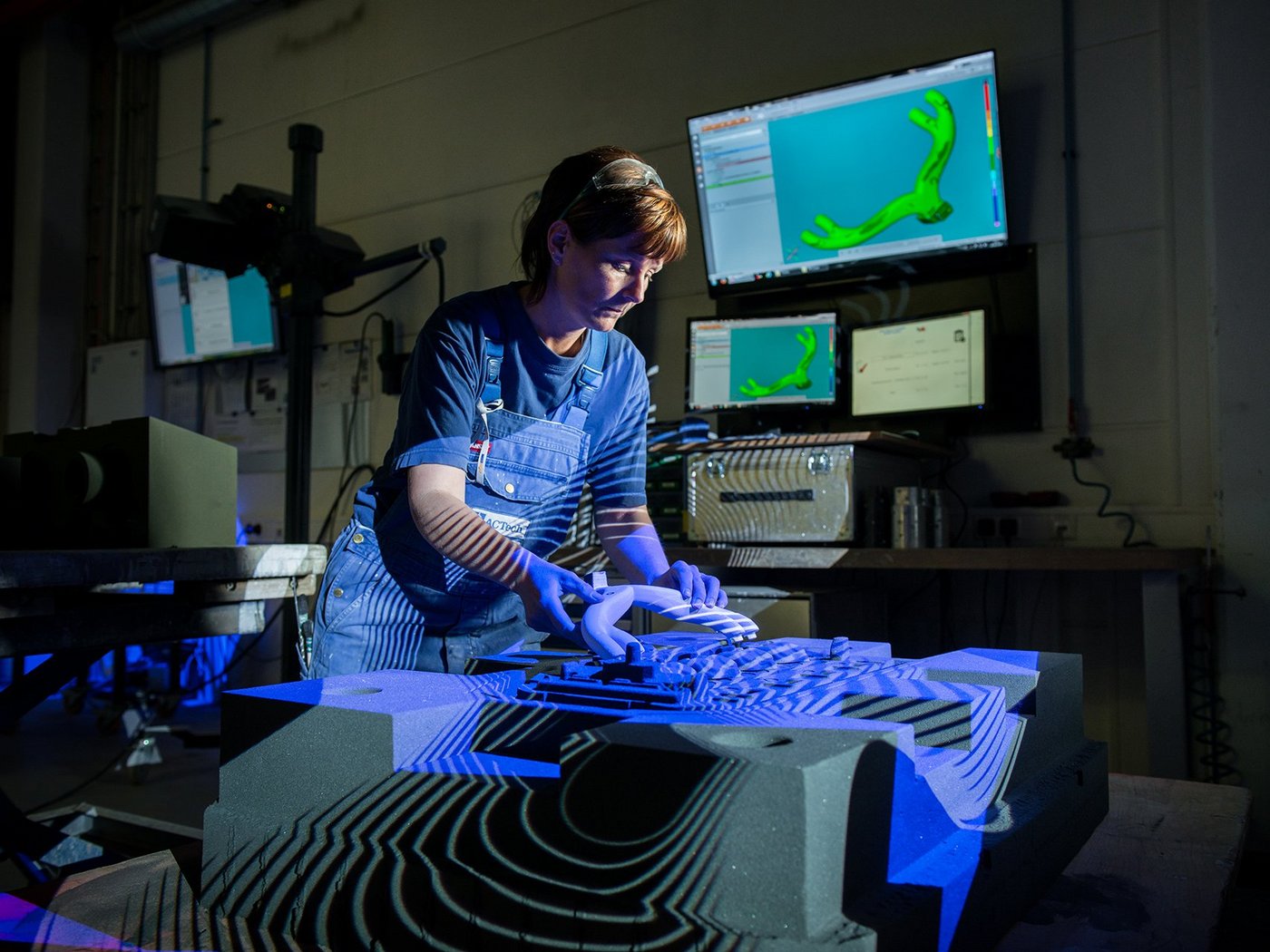

Whether aluminum, cast iron or steel: Where other suppliers limit themselves to a single material, with ACTech you 'all in' with metal casting – and benefit from a wide spectrum of casting materials. We have the technology and expertise to process all standard alloys as well as special and customer alloys – and for single components on request.

Metal casting in all common steel, iron and aluminum alloys

Versatile sizes and quantities of units

Realization of complex geometries and challenging materials