The fast, safe and low-emission transport of people and goods by rail demands consistently new developments in rail technology. This often concerns especially large and heavy components or assemblies – in such situations however, many prototype foundries reach their limits. ACTech is different: We upgraded our capacities and processes to the production of castings for railroad transport several years ago.

Large dimensions are primarily required for prototyping in the railroad technology sector.

High safety stipulations also necessitate extensive quality assurance, testing and documentation processes.

Special certifications must be present for permission to produce castings for the railroad or for welding assemblies.

We are up to any requirement!

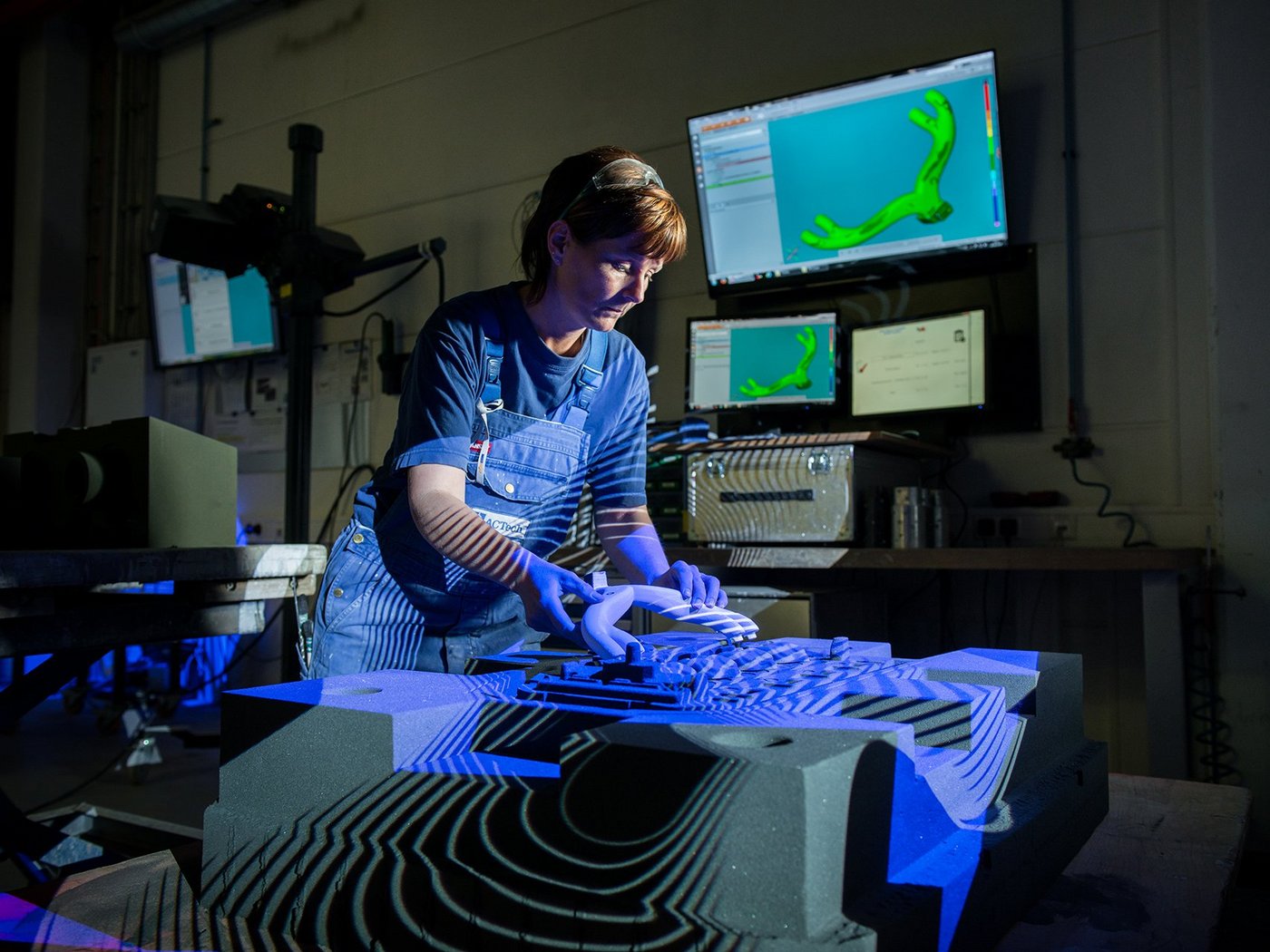

Diesel engine components, turbochargers and chassis – parts for railway vehicles significantly exceed the standard in terms of size and weight. This is why ACTech upgraded years ago: We currently work with larger 3D printers, guarantee above-average casting capacities and have a constantly expanding machining division. We also handle large, heavy castings for railway transport while ensuring our usual high quality. Certified at ACTech: all necessary proofs for the production of castings for railway vehicles and for the welding of assemblies. Another plus: Extensive quality assurance along the entire process chain is always on board with us.

Certifications for railroad technology

We have the necessary qualifications to produce castings for railway vehicles and for welding assemblies. We have been audited by DVS ZERT and are certified for the production welding of railway vehicles and vehicle parts. Our quality management system has also been certified by the 'TÜV SÜD Management Service GmbH' certification center according to ISO 9001.

TÜV SÜD

Quality policy

Is ACTech certified for railroad technology?

Is ACTech certified for railroad technology?

ACTech was audited by DVS ZERT in 2020 with confirmation that the welding operations meet the requirements of DIN EN 15085-2 at certification level CL1 for the field of production welding. This standard is the basis for welding metallic materials in the production and repair of railway vehicles and vehicle parts.

What are the special requirements for railway vehicle castings?

What are the special requirements for railway vehicle castings?

Castings for railway vehicles and also for stationary railroad technology facilities are generally massive and large. Nevertheless, developers attempt to save material and thus weight in the interests of energy efficiency. Traditionally, and particularly for undercarriages and drive systems, steel and iron materials have been the main materials used in railroad technology.

Are the drive systems for railway vehicles also changing?

Are the drive systems for railway vehicles also changing?

Alternative drive concepts are not only being created for road transport. The complete transportation sector, both passenger transport and freight, is undergoing a transition. It is thus not surprising that alternative drive systems such as hydrogen fuel cells also play an important role in current railway vehicle concepts.

What opportunities do casting prototypes provide in railroad technology?

What opportunities do casting prototypes provide in railroad technology?

Until now there have only been a few suppliers for fast, fully functional prototypes due to the high quality requirements prevalent in railroad technology and the dimensions of parts. Fully machined castings as single pieces enable rapid development projects for the railroad industry and its peripheral sectors. Different concepts can be tested simultaneously and new ideas quickly get on-track.