Low-emission drive technologies and alternative fuels are playing an increasingly important role with regard to climate change and the scarcity of resources. In order to implement innovative ideas in a timely manner, expertise and speed are required in the production of prototype parts. We at ACTech guarantee both and accompany you on the way to a clean future: With our many years of experience, we manufacture innovative castings for alternative drive concepts – for passenger cars, commercial vehicles and construction machinery.

There is a huge amount of time pressure in the race for market share regarding passenger cars, construction machinery and commercial vehicles with alternative drive concepts.

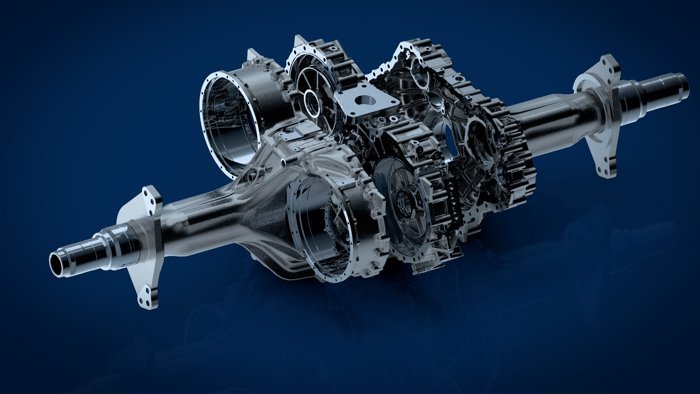

Highly complex castings, for example liquid-cooled e-drives with different gearboxes, demand maximum precision and know-how in production.

Hydrogen-based drive technologies in particular involve completely new types of material requirements.

With us you'll achieve your goal!

Overcoming challenges, expanding the limits of what was previously possible and forging a common path with ACTech means we stand by you as problem solvers. New technologies, material testing and the optimization of our internal processes constitute our daily agenda. We aim to make a difference – for you and for our planet. This is why we guarantee short production and delivery times and maximum precision for alternative drive castings – ranging from mold construction to CNC machining. Even complex specifications in terms of parts geometry and materials do not hold us back. After all, we take pride for good reason in our experience with more than 230,000 metal prototypes and our higher-than-average portfolio of materials.

TÜV SÜD

Quality policy

TÜV SÜD

Environmental policy

Does ACTech only manufacture parts for the automotive industry?

Does ACTech only manufacture parts for the automotive industry?

If you require a newly developed metal part, we can rapidly and reliably produce high-quality prototypes or small batches, regardless of the industry. The automotive industry is of high significance to ACTech, but is by no means the only sector we work with. We also manufacture parts for trains, ships and helicopters and produce tools and pumps. Future-oriented, environmentally friendly technologies also need our support. Ultimately though, each and every customer we work with is primarily concerned with quality and speed.

What are the typical castings in alternative powertrains?

What are the typical castings in alternative powertrains?

The diversity of parts and components that can be realized in casting ranges from complex gearbox housings, electrified axles and e-motors to structural components for new vehicle concepts. Even familiar castings such as combustion engines are being redeveloped for hybrid concepts and hydrogen applications.

Do electric motors have complex castings?

Do electric motors have complex castings?

We have witnessed a consistent increase in the complexity of cast components in recent years. In electric motors as well, topics such as function integration (e.g. integrated cooling) and component integration (e.g. component merging of electric motors and inverters) are gaining in importance.

Do alternative drive technologies result in further changes to vehicle concepts?

Do alternative drive technologies result in further changes to vehicle concepts?

New technologies are leading to a revision in vehicle concept development. In addition to new components, familiar structures are also being reconsidered. One example is the casting of complete chassis structures and bodies. The choice of manufacturing technologies is also evolving, not only in terms of drive technologies but also with regard to faster prototypes and shorter production cycles.