In this article, we debunk four widespread myths and explain why cast parts are often the best choice for numerous applications.

Fallacy or Reality? 4 Myths About Castings

It is often assumed that cast parts are exclusively intended for serial production and require expensive casting molds.

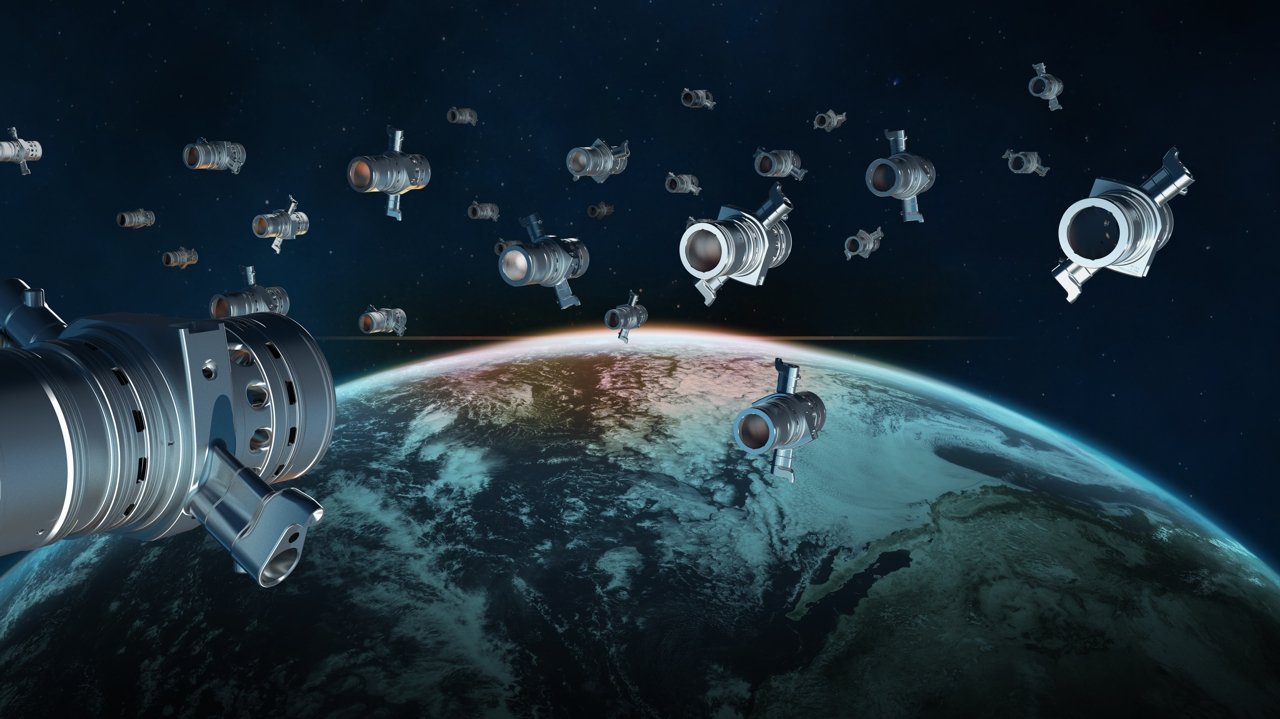

By using 3D-printed sand molds, the costs and lead times for castings can be significantly reduced without the need for costly tooling investments. This innovative technology opens up new possibilities for small series production and prototypes. ACTech is a pioneer in additive manufacturing and operates various 3D printing systems, enabling the rapid production of sand casting prototypes.

A common belief is that producing cast parts is associated with lengthy lead times.

In reality, complex castings with series-level quality can be available in as little as 2-3 weeks. Thanks to modern technologies such as casting simulations, 3D-printed mold segments and cores, and optical measurement techniques for quality control throughout the entire process, cast parts can be manufactured in record time.

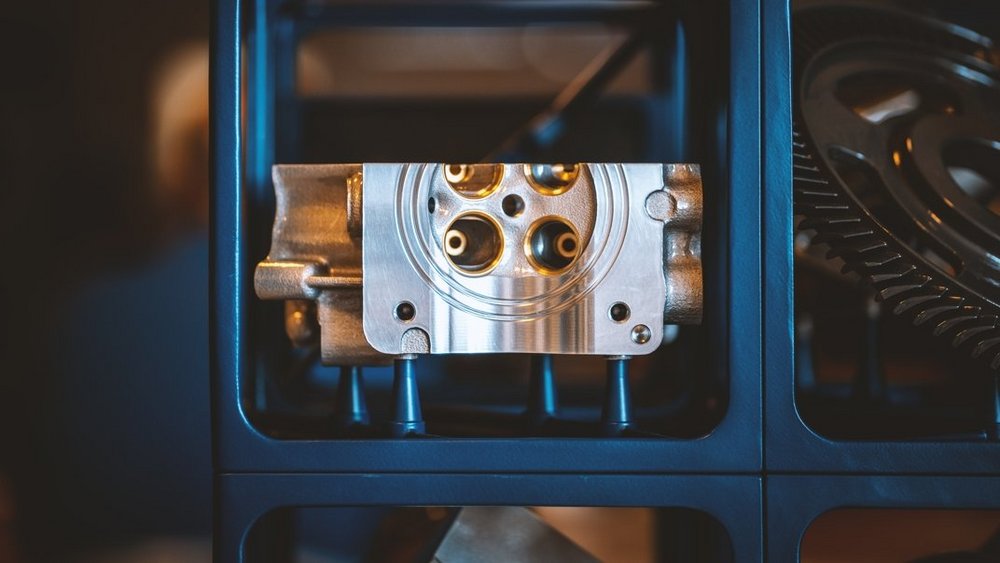

Another myth is that producing prototypes from solid metal blocks is the fastest option. While this method does have some time advantages, manufacturing prototypes from solid material has its limitations, particularly for components designed for series production in casting or with high complexity.

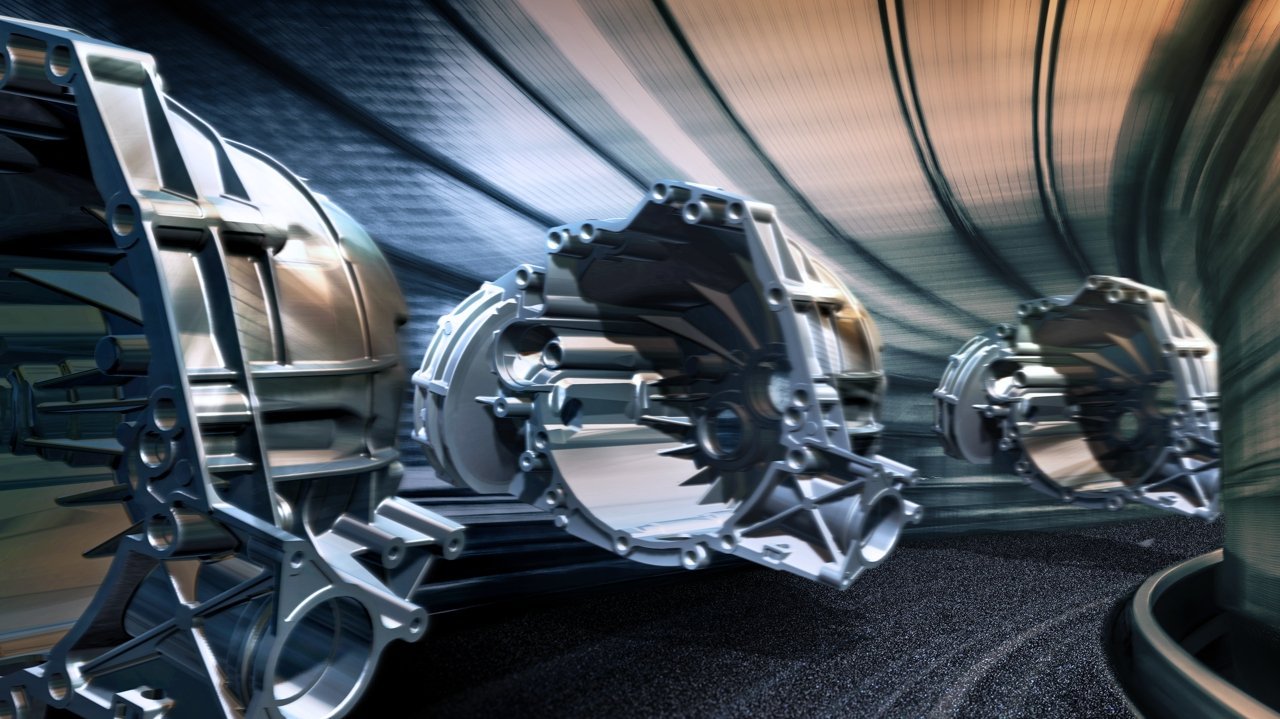

Prototype casting remains the best solution for complex designs, such as gearbox housings, electric motor components, or engine parts, especially when quick delivery and series-like properties are required.

At ACTech, we go "all in" on casting production, including state-of-the-art CNC machining – with all processes handled in-house. We evaluate the best option for every component.

There is a widespread belief that metal 3D printing will soon replace casting entirely. While M3DP offers fantastic possibilities for specific designs and applications, it is still subject to limitations regarding size, quantity, and material diversity. For instance, proven cast iron materials cannot be replicated due to their solidification characteristics.

Our mission is to find the best solution for every project and design. As part of "Materialise," we work closely with the M3DP team in Bremen to provide our customers with the most suitable technology, whether it involves casting or M3DP.

Conclusion

Casting offers numerous advantages and possibilities that are often overlooked. By challenging these myths, we aim to create a better understanding of the potential of this technology. At ACTech, we are committed to providing our customers with the latest technologies and solutions to ensure successful project execution.

Let's find out together how cast parts can be the best choice for your requirements too.