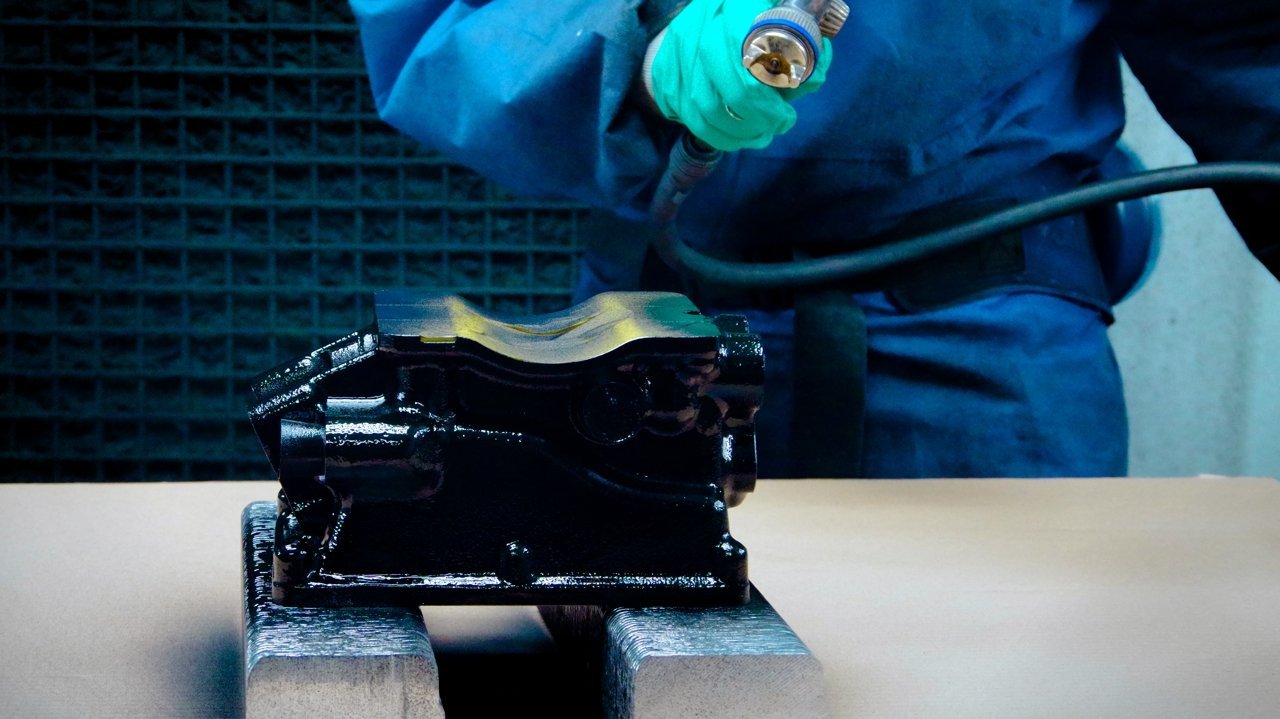

Depending on the final application, we can treat the casting surface using various methods to meet your specific requirements. This ensures you receive a ready-to-install prototype – all from a single source. We specialize in the most common coatings for optimizing component properties.

One effective base coating for further processes is the treatment with 2K epoxy primer filler. This coating already provides excellent corrosion protection and high durability. Additional beneficial properties can be achieved through the application of further coatings.