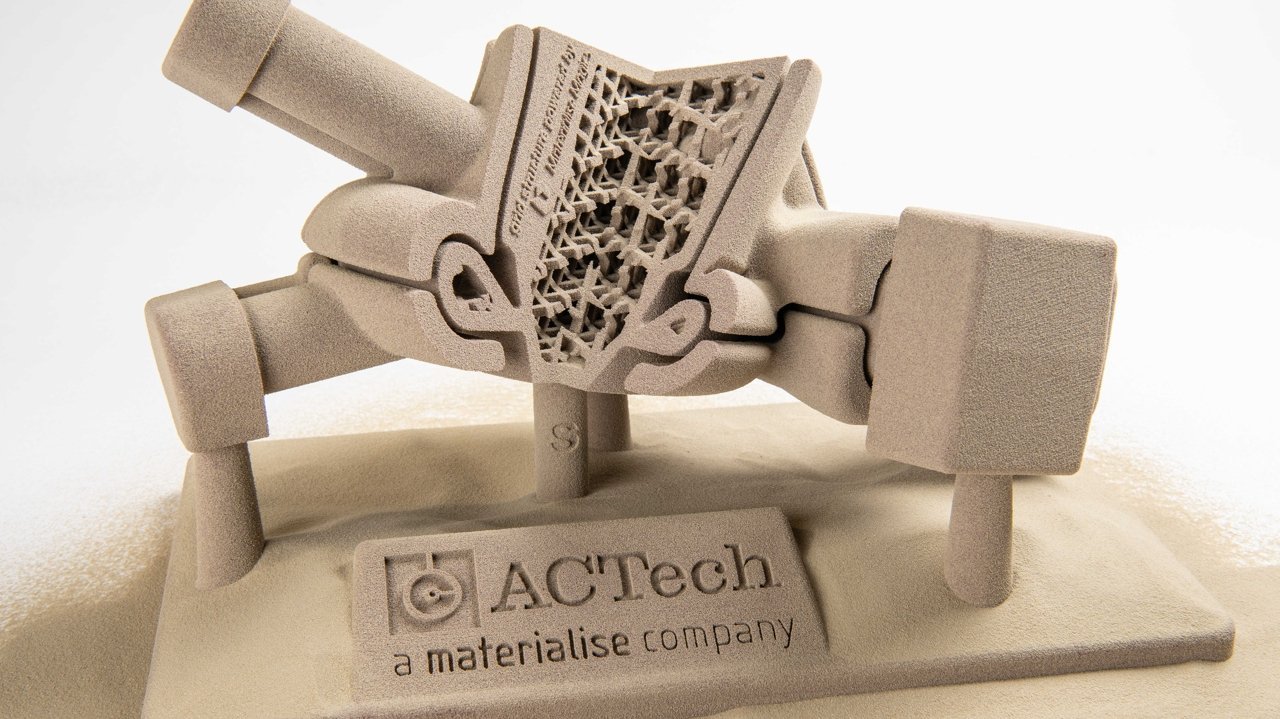

This is where we at ACTech come in. Since 1995, we have been pioneers in advancing casting production using additive processes, leveraging the innovative sand printing method.

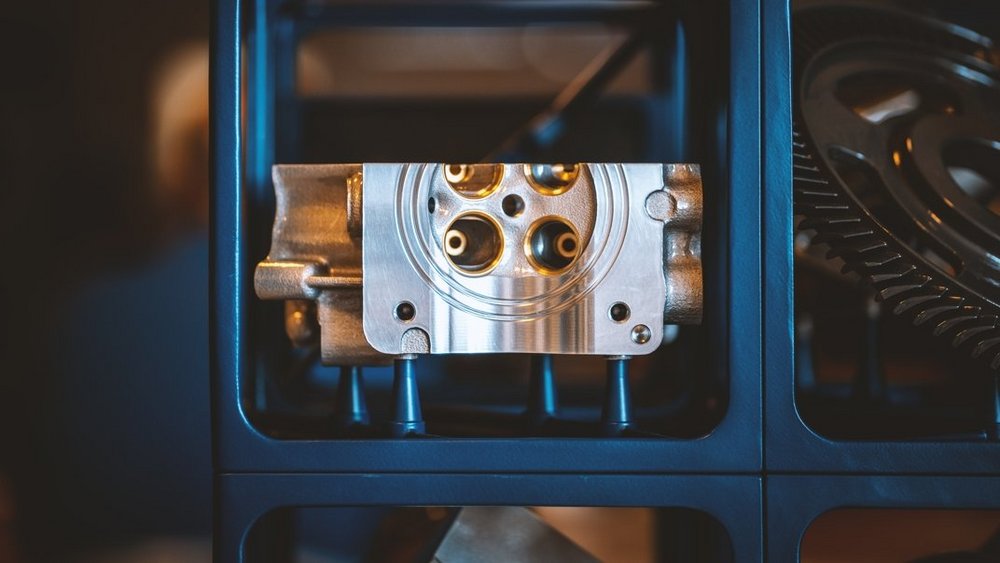

In this blog article, we aim to highlight the numerous advantages of this process and demonstrate how it is redefining the production of casting molds.

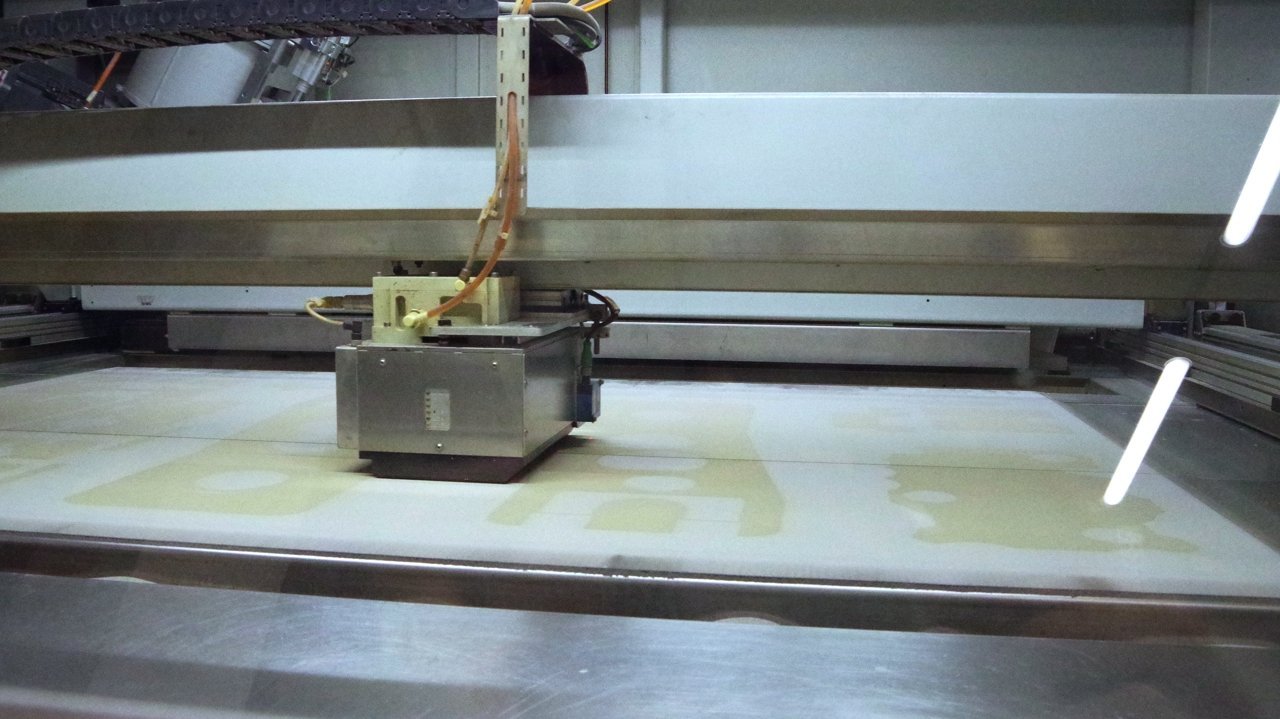

The sand printing process, also known as 3D sand printing or binder jetting, provides a solution to many typical challenges in casting production. By using a foundry-compatible mold material paired with a binder for solidification, highly complex geometries can be realized, and specific customer requirements can be met with precision.